-

Call Now:

+61 1300 069 973

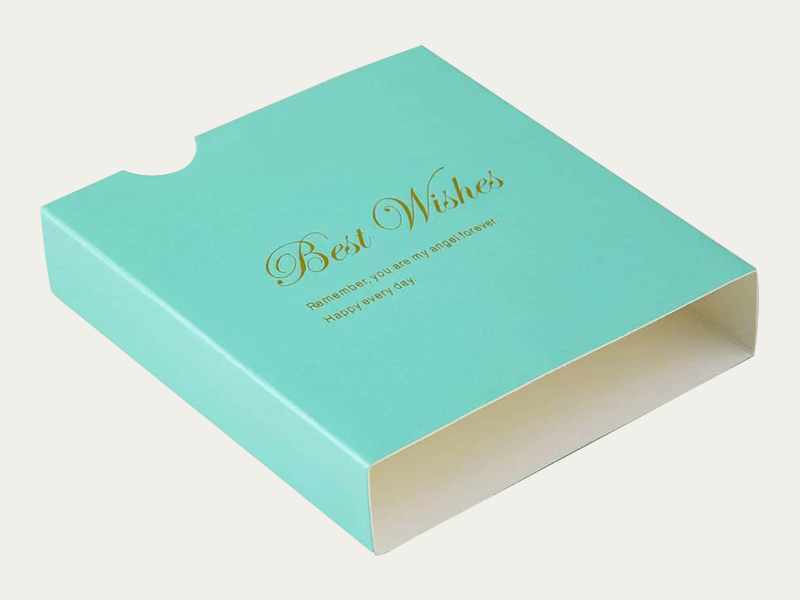

Build a Positive Brand Image with Slide-to Reveal Unboxing Thru Splendid Sleeve Boxes

Choose from premium stock to eminent printing and even 10+ coating here to craft marvellous sleeve boxes for presenting high-end products, gift items, and special editions with slide-out extraction. Get wholesale rate with free shipping. Start now and create an edge in the market.

Get Custom Quote

Meeting Every Packaging Need is our Commitment to Excellence in Tailored Solutions

With savvy packaging experts, modern technology, and structured production procedures, YBY Boxes commits to delivering the highest-quality boxes in all shapes, styles, sizes, and printing at unbeatable prices. Our dedication to excellence and years-long experience in both production quality and meeting customers’ expectations sets us apart in the market, ensuring that you receive top-notch boxes that won't break the bank. Trust us to fulfil your packaging needs with unmatched value and quality.

Give Your Product an Elegant Slide-Out Extraction While Maintaining the Quality, and Amaze the Recipients with Astoundingly Designed Sleeve Boxes

Sleeve boxes are a combination of two parts i.e. sleeve and tray. A sleeve, aka belly band packaging, which is a piece of paperboard with open ends while the tray is a box shape with an open top. When the sleeve is wrapped around the tray, it is conjointly called “sleeve boxes” or “drawer packaging”. The sleeve provides an additional layer of protection to the main box (tray), which slides seamlessly into the sleeve. This dual-layer design offers increased durability, ensuring your product is secure and well-protected during transit and handling. It also adds an element of suspense to the unboxing experience as customers slide the outer sleeve to reveal the product inside, enhancing customer engagement and satisfaction. This dual combination of protection & presentation with impressive pull-out behaviour makes sleeve boxes the ideal packaging for various products such as pens, keychains, macarons, bandana, vape, and other items. Their flat base also works wonderfully and gives you the freedom to place them anywhere on the retail shelf. Overall, sleeve boxes give your inside-packed product a stylish feel, protective storage, strong brand identity, and jaw-dropping pull-out unboxing. It seems that creating them is quite easy but in reality, it’s not, a minor mistake in dimension can ruin your sleeve box design. But YBY Boxes offers you unique, secure, and innovative custom sleeve boxes per clients’ requirements. From printing, and designing to manufacturing and shipping, we take care of every single step to ensure you get top-notch sleeve boxes the way you want. By utilising advanced die-cutting machines, we manufacture custom sleeve boxes with exact dimensions, the sleeve is slightly larger than the tray, so they can easily be wrapped or unwrapped over the tray. Whether you want sleeve boxes with thin inner trays to make them ideal for lightweight products or thick inner trays to work as inserts and protect fragile products, just inform us and we got you covered. Except this our expert designers are always at your service to facilitate you and provide you with sleeve boxes the way you want, all you need is to just find your way towards us.

Inject an Appealing Visual to Your Product, Grab Customers Attention, and Create Brand Recognition with Elegantly Printed Custom Sleeve Boxes

Sleeve boxes with slide-to-reveal unboxing are the ideal packaging for gift and promotional items during business promotions, gift-giving, fundraising, or any other event. But only unboxing is not enough you have to make sleeve boxes captivating yet branded. For this, print beguiling design or invoking colour patterns on your sleeve boxes to make them perfect attention-grabbing contrivance and win recipients’ hearts during product launch. Apply gold foil on your printed branding element on sleeve boxes to make them more prominent and put your competitors in the dust. It seems quite easy but creating them without any single error or misprinting is not as simple as it seems. It takes a lot of expertise and advanced technology to create sleeve boxes with a professional look that matches your business branding. But why are you worried? By selecting YBY Boxes as your box provider you already have solutions to your all problems related to packaging. We impeccably print your required artistic design, thematic colour contrast, and branding emblems on sleeve boxes without any blur or splatter by using our state-of-the-art printing press. To make sure our client and technical staff are on the same page while selecting the colour code, we use a rainbow colour scheme. We also offer various minimalist font options so you can print the text on sleeve boxes in stylish yet bold form to make your message clear and loud. But we know uncoated boxes can’t achieve what coated boxes can, therefore; we offer you a wide range of finishes and coating such as emboss, deboss, foil stamping, gloss, matte, or spot UV. Choose any one according to your preference and make your sleeve boxes more noteworthy and enthralling. In case you want to add any embellishment to your sleeve boxes inform us and you can also browse our above-mentioned portfolio for amazing designs.

Custom Sleeve Boxes a Versatile Packaging Solution

Explore the multifaceted benefits of custom sleeve boxes, a versatile packaging solution that solves numerous challenges businesses face today:

- Cost-Effective Packaging

- Branding and Customization

- Versatility in Function

- Eco-Friendly Solutions

Get Your Hands on Plentiful Customisation Options to Create Extraordinary Sleeve Boxes for Upscale Presentation, Protection, and Branding

We at, YBY Boxes know the importance of sleeve boxes and believe they not only offer pull-out openings but also work ideally for presentation, protection, and branding when utilised properly. Here, we come with a wide range of personalisation choices that help you create sleeve boxes the way you want to fulfil your all requirements. Are you excited to know those customisation choices? If yes, then come:

High-Quality Stocks:

Choose from plentiful premium yet sturdy material options including rigid, cardboard, or kraft to make your sleeve boxes more protective and appealing.

Eminent Printing:

Mix and match various colour contrasts with catchy designs to create your desired look on sleeve boxes and make them more attractive even from afar.

Exact Box Dimensions:

Whether you want to pack a vape, pen, or macaron, pick our accurate box dimensions as per your product nature to give them an ideal fit.

Functional Add-ons:

Add ribbon pull to your sleeve boxes to make them perfect for gift-giving, upgrade their sliding opening and stun the receiver with added lasting impact.

Amazing Finishes:

Opt for various finish choices such as foil stamping, emboss, deboss, gloss, spot UV, or matte for your sleeve boxes to make them presentable and noteworthy.

Custom Inserts:

Add custom inserts (cardboard inserts, foam inserts, or cross-partitions) in your sleeve boxes to make them more functional with a wonderful backdrop.

By utilising immense approaches, the latest printing and die-cutting equipment and innovative techniques for printing and manufacturing boxes, we give you the full authority to customise sleeve boxes according to your product specifications. Moreover, whatever your demands are including material, size, printing, add-ons, or coatings, just let us know and we will get you covered with 100% perfection and precision. To give you a feeling of satisfaction, we offer you a free 3D prototype to ascertain whether the box design is according to your specifications or not.

Why You Should Invest in Custom Sleeve Boxes?

Custom sleeve boxes are not just a packaging solution with nifty slide-out extraction; they are the complete package of presentation, protection, and branding. Here, is the top listed benefits of why you should invest in custom sleeve boxes:

- Offer slide-pull extraction of the inside product.

- Present your product with ample protection.

- Offer a fantastic platform for branding and customisation.

- Can be tailored in terms of stock, size, design, and add-ons to make them more functional and striking.

Now Ordering Exclusive Sleeve Boxes as You Desire is Quite Simple with YBY Boxes

We believe that with plentiful customisation options for boxes, you should provide some ease to the customers so they can easily order what they want. By keeping this in mind, we convert our nerve-wracking procedures into simple processes. Excited to know those easy-to-access steps? Without wasting any time let’s have a glimpse at those ways:

Custom sleeve boxes will become the tongue of your brand, therefore; they should be made from high-quality stock that dazzles every customer. The material you choose should be protective & presentable at the same time. After finalising the material go for custom size and shape for sleeve boxes according to your product nature. To make them perfect gift-giving packaging you can apply chic finishes and add functional add-ons, enhancing the customer experience. Upload the box design in PDF format and ensure it contains all the elements of presentation and branding. Decide the number of boxes you want, clear the payment at checkout, and get your order delivered to your doorstep with the fastest yet secure shipping.

Why You Should Choose YBY Boxes as Your Box Provider?

We have been in this field for more than two decades. It’s our commitment to quality and reasonable prices that put us at the top of the list. We always prioritise customer and their needs therefore we have satisfied customers in almost all niches. Whether it’s the premium yet durable stock, intriguing design, custom size, stunning coatings, and functional add-ons that you want for your sleeve boxes, we provide you all with a wide range of customisation options. Now gracefully present your product on the shelf, create hype for your brand, and establish a connection with your customer through our custom-printed sleeve boxes. What? Do you want boxes in minimum quantity? No worries. Order as minimum and maximum boxes as you want for your product with our no-minimum order restrictions. For us, no order is small or large, and we facilitate every single brand with the same level of quality, service, and value. If you’re further worried about the final design, let me be very clear we provide our customers with free 3D prototypes by which customers can ascertain whether the box design is according to their needs or not. If it’s not, then you can avail of our free design assistance by which you can add or remove any element from the existing design and make it free from any error or ambiguity.

Once the final box design is decided, we will deliver your order to your doorstep at the selected time. Our turnaround time is about 12-14 business days but in case you want speedy delivery, you need to request us, and that will be charged extra hope you can understand. To make your packaging journey smooth and easy with us, our customer care representative is 24/7 available for your help during printing, designing, manufacturing, and shipping processes. To get an instant quote, dial +61 1300 069 973. You can also contact us through message and live chat.

Your Vision, Our Proficiency: Crafting Bespoke Packaging, Step by Step

At YBY Boxes, we pride ourselves on making the process of ordering custom packaging as simple and straightforward as possible. In just four easy steps, you'll be on your way to receiving your own unique, high-quality boxes.

Design it

Customise your boxes with the desired size, shape, and style.

Print It

Upload your artwork, and we'll expertly print it to your exact specifications.

Get It Done

Order any quantity and benefit from our wholesale pricing, with no extra charges for die plates.

Receive It

Our order will be delivered to your doorstep with a quick turnaround time and complimentary shipping.

Below you'll find answers to some common questions around creating a custom Sleeve box. Still have something to know about? Contact us at +61 1300 069 973.

No, we don’t restrict our customers in choosing whatever number of boxes they require. Enjoy the flexibility here to order as few boxes as you like.

Yes, you can definitely do so. But on the contrary, if you don’t have a design of your own then our experts are always available for your assistance to turn your vision into a tangible product.

Our standard production times typically range from 7 to 9 business days. However, if you need boxes in a hurry, choose for expedite option.

Yes, all of our boxes are always made from biodegradable, reusable, and recyclable materials and printed with chemical-free inks.

Yes, you can. Just fill out the quote form with your contact information and specific sample requirements.

We offer multiple convenient payment methods, including:

- Visa

- MasterCard

- American Express

- Discover

- PayPal